News and Events

- Pandemic rural residential mobilities? Towards an understanding of who moved house and why in rural Ireland

- Dr Luke Kelleher co-leads a new EPA-funded project

- Exciting International Collaboration with Kazakhstani Exchange Students

- New Chapter for China Joint Colleges: Meet the New Director

- The Long Journey Across Cultures: My Intercultural Adventure from CDIC to Chang’an University by Zhao Ruixiang

- CDIC Team Secures ReClaim Funding to Enhance Inclusion for Migrant Researchers

- Dr Jufan Zhang is the finalist of 2024 UCD Research Impact Case Study Competition

- New Lecturer Joins Civil Engineering Infrastructure Programme

- 2nd China Joint Colleges Workshop

- Salt Medical and Dr Jufan Zhang Join Forces to Revolutionise Nano Manufacturing of Medical Devices

- Dr. Aasifa Rounak receives Teaching Excellence Award

- Automotive Design Competition 2024

- Studio/coursework of undergraduate students at CDIC acknowledged in published journal articles

- Dr. Devon Kerins Welcomed to CDIC Team

- Fully-funded PhD opportunity in Transformations to Sustainability

- CDIC students top winners of the 29th "21st Century Cup" National English-Speaking Competition

- CDIC Design Studio established

- Visiting PhD Student Huitian Liu Publishes Research on Electric Vehicles

- Quiz: solution to good class attendance

- Students 2024 Welcome!

- Knowing the City: Unveiling the Planning and Development of Xi’an and Beyond CDIC-TCPEP Lecture Series

- Four CDIC EAP teachers successfully completed the Professional Certificate in TESOL

- Navigating the Challenges and Opportunities - Li Yansen

- Embracing challenges - journey of Zou Jiangyu

- My journey at CDIC - Cao Danning

- Balancing Passion, Academics, and Personal Growth – Feng Junkai

- Joy of Learning and Building Connections – Zhao Haiyi

- Debate on my experience - Wang Li

- Passion, Learning, and Balance – Liu Hanyang

- Dr Caterina Villani finalist for the RTPI Awards for Research Excellence 2024

- We welcome new Autumn UCD/CDIC teacher

- CDIC Graduates, Congratulations

- CDIC English Teachers Visit UCD

- President of Chang'an University visited UCD

- Dr Yunpeng Zhang on seeing China from Europe

- AE class visit to car manufacturing factory in Xi'an

- And the UCD Innovation Award goes to... Dr Nan Zhang

- Bridge the Rent Gap conference

- UCD delegation visited HAUST

- Spring in CDIC

- CDIC Warriors

- St Paddy's Day celebration in CDIC

- CDIC English teachers got their TESOL certificates

- We welcome CHD PhD student Huitian Liu

- Exploring Street Experiments in High Density Urban Asia

- Dr Luke Kelleher on barriers, drivers and potential for innovation

- Automotive Design Competition 2023

- Our teachers celebrating new CDIC students

- New Automotive Engineering teacher joins CDIC

- Design 2 Bridge Design Competition

- Faculty & Students Experience Sharing

- Dr Nan Zhang recognised as 2023 Rising Star

- We welcome our new Automotive Engineering lecturer

- Dr Ana Peric Momcilovic honoured with the Gerd Albers Award

- Inspiring journey across borders

- Welcome Freshers!

- Welcome to the Academic Year 2023-2024

- New teacher welcomed for the new academic year

- Dr Nan Zhang revolutionises point-of-care diagnostics & the biopharmaceutical industry with Microfluidics

- First CDIC Student finishes her programme in Dublin

- 2023 CDIC Graduation Ceremony

- CDIC English Teachers Visit Dublin

- TCPEP Teachers' First Experience of CDIC

- We Welcome New TCPEP Teacher Caterina Villani

- CDIC Funded Student Presenting in Oxford

- Follow Your Passion - Interview with CDIC Student

- Meet the CATs!

- CDIC Students Performing on the Roof

- We Met to Talk About Irish Culture

- CDIC Students Learning How to Play Tin Whistle

- UCD wins the Asia Matters 2022 Higher Education Partnership

Revolutionising point-of-care diagnostics and the biopharmaceutical industry with Microfluidics

Tuesday, 18 July, 2023

Microfluidics, the science of manipulating and controlling small amounts of fluids, is making significant strides in improving point-of-care diagnostic devices. Dr. Nan Zhang, an assistant professor in the School of Mechanical and Materials Engineering here at University College Dublin, CDIC Lecturer and a researcher in microfluidics, is at the forefront of this exciting field.

In what is often referred to as ‘lab on a chip’ science, his research focuses on developing mass production technologies to bring innovative diagnostic devices from the laboratory to patients at an affordable cost.

The challenge lies in scaling up the production process. These microscale and nanoscale channels have dimensions close to the diameter of the average human hair. Therefore, making these microfluidic devices in high quantities while maintaining consistency and repeatability without defects is difficult.

“Generally these devices are made using a laboratory based method, a lithography process, which is expensive and not easy to scale up”, explained Dr. Zhang.

“You can make a few pieces, even tens of pieces, in a lab but how can you make hundreds or thousands with good consistency and without defects? That's the challenge,” he added.

Dr. Zhang and his polymer micro/nano manufacturing technologies group are addressing this problem by designing these channels and developing high precision replication technology for large-scale production.

It’s a long process that has taken ten years from the design phase to mass productionto establish the lab from scratch.

Now the process established This includes designing the microfluidic channels, running simulations to optimise fluid dynamics, and prototyping using precision 3D printing and micro-machining technology. It is followed by conducting various experiments to test these tiny channels, such as nanoparticle synthesis or diagnostic tests.

Dr Zhange described the next steps: “If successful, we move to small-scale production for patient trials or customer validation, using our self-lubricating moulds and replication technologies like microinjection moulding, micro hot embossing, and nano imprinting. To create closed channels, we develop surface treatment and bonding techniques.”

“Our technology is scalable, allowing for laboratory-scale prototyping as well as the production of hundreds to thousands of samples. This ensures consistency and translation from lab testing to small-scale validation and eventually mass production,” he pointed out.

While there are other research groups working on microfluidic devices, what is unique about Dr. Zhang research is the development of a breakthrough advancement: High precision self-lubricating micro moulds.

This technology helps to produce defect-free microfluidic devices while extending the mould's life by up to five or six times, making it more cost-effective.

“I developed a mould that can help release the plastic from the mould itself; you can easily separate the polymer from the mould without inducing any kind of deformation or adhesion defects,” said Dr. Zhang.

“Also, the technology I developed can actually extend its life, which is important because they are quite expensive, between €8,000 and €15,000 for one single mould.”

Microfluidic devices have a wide range of applications and are increasingly becoming an important part of modern medicine.

Within point-of-care diagnostics this includes blood and urine tests, but also, as Dr Zhang points out, emergency situations for life-threatening diseases including the timely detection of sepsis, a condition caused by the body's response to an infection that can lead to organ failure and, if not treated promptly, can result in high morbidity and mortality rates.

Another significant application of microfluidics, which is where Dr Zhang and his group’s interests lie, is in the biopharmaceutical industry in the synthesising of nanoparticles, such as those used in mRNA vaccines.

These vaccines require a carrier to protect the genetic material, and optimising the formulation of these carriers is crucial for effective and safe delivery, explained Dr. Zhang. Microfluidic devices can be used to screen and optimise formulations, speeding up the drug development process and improving treatment outcomes.

Microfluidics also play a crucial part in gene therapy, an emerging treatment modality that involves introducing, modifying, or repairing genetic material within a patient’s cells, and which holds great potential for cancer treatment.

Where microfluidics comes in is the ability to manipulate small volumes of fluids, which is increasingly employed to facilitate gene therapy approaches for cancer treatment, offering several advantages such as precision, speed, and scalability.

“You need optimise those formulations to make sure that these nanoparticles can be targeted to certain organs like for breast cancer or some other cancers; you need to make sure those nanoparticles can recognise the organ that the cancer is in”.

How do you optimise such formulations? You need to use microfluidic devices like the ones Dr Zhang and his research group are working on.

“We have developed a high throughput formulation optimisation system that can help gene therapy companies, cell therapy companies and some CDMOs (contract development and manufacturing organisations) to screen and optimise their formulations to ensure these genetic materials are well protected and can be targeted to certain tissues or organs,” explained Dr. Zhang.

“This is quite important because those biopharma companies have spent years and years developing the best drug formulation to treat certain diseases and we can really help them to accelerate the process and eventually bring the overall therapy to the patient much quicker than you normally would.”

Dr. Zhang’s group is currently collaborating with SINTEFyntec, a leading European scientific instruments company, as well as a US gene therapy company. These partnerships are a testament to the potential of his team’s technology in revolutionising healthcare and providing life-changing benefits to patients.

The microfluidic devices designed by Dr. Zhang are not only paving the way for faster, more accurate diagnostics but also helping to optimise drug formulations for gene therapy and cell therapy.

The potential applications are vast, and the impact on healthcare is profound. With continued advancements in microfluidics, we can expect to see even more innovative diagnostic and treatment options become available, transforming the way we approach healthcare and improve patients’ lives.

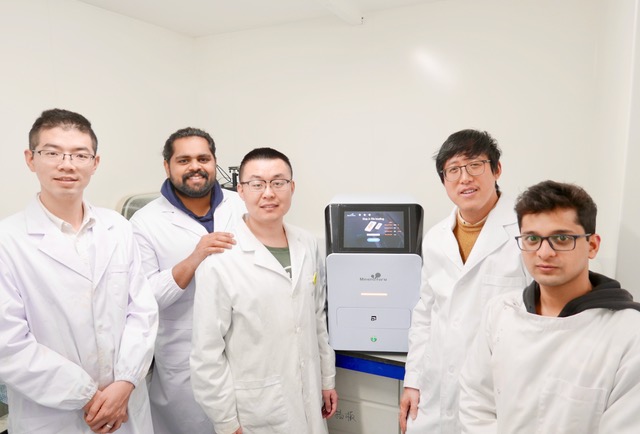

Below Dr Zhang with his team of researchers and MiNano-form: a high-throughput nanoparticle formulation system and the microfluidic cartridge developed at UCD.