News and Events

- Pandemic rural residential mobilities? Towards an understanding of who moved house and why in rural Ireland

- Dr Luke Kelleher co-leads a new EPA-funded project

- Exciting International Collaboration with Kazakhstani Exchange Students

- New Chapter for China Joint Colleges: Meet the New Director

- The Long Journey Across Cultures: My Intercultural Adventure from CDIC to Chang’an University by Zhao Ruixiang

- CDIC Team Secures ReClaim Funding to Enhance Inclusion for Migrant Researchers

- Dr Jufan Zhang is the finalist of 2024 UCD Research Impact Case Study Competition

- New Lecturer Joins Civil Engineering Infrastructure Programme

- 2nd China Joint Colleges Workshop

- Salt Medical and Dr Jufan Zhang Join Forces to Revolutionise Nano Manufacturing of Medical Devices

- Dr. Aasifa Rounak receives Teaching Excellence Award

- Automotive Design Competition 2024

- Studio/coursework of undergraduate students at CDIC acknowledged in published journal articles

- Dr. Devon Kerins Welcomed to CDIC Team

- Fully-funded PhD opportunity in Transformations to Sustainability

- CDIC students top winners of the 29th "21st Century Cup" National English-Speaking Competition

- CDIC Design Studio established

- Visiting PhD Student Huitian Liu Publishes Research on Electric Vehicles

- Quiz: solution to good class attendance

- Students 2024 Welcome!

- Knowing the City: Unveiling the Planning and Development of Xi’an and Beyond CDIC-TCPEP Lecture Series

- Four CDIC EAP teachers successfully completed the Professional Certificate in TESOL

- Navigating the Challenges and Opportunities - Li Yansen

- Embracing challenges - journey of Zou Jiangyu

- My journey at CDIC - Cao Danning

- Balancing Passion, Academics, and Personal Growth – Feng Junkai

- Joy of Learning and Building Connections – Zhao Haiyi

- Debate on my experience - Wang Li

- Passion, Learning, and Balance – Liu Hanyang

- Dr Caterina Villani finalist for the RTPI Awards for Research Excellence 2024

- We welcome new Autumn UCD/CDIC teacher

- CDIC Graduates, Congratulations

- CDIC English Teachers Visit UCD

- President of Chang'an University visited UCD

- Dr Yunpeng Zhang on seeing China from Europe

- AE class visit to car manufacturing factory in Xi'an

- And the UCD Innovation Award goes to... Dr Nan Zhang

- Bridge the Rent Gap conference

- UCD delegation visited HAUST

- Spring in CDIC

- CDIC Warriors

- St Paddy's Day celebration in CDIC

- CDIC English teachers got their TESOL certificates

- We welcome CHD PhD student Huitian Liu

- Exploring Street Experiments in High Density Urban Asia

- Dr Luke Kelleher on barriers, drivers and potential for innovation

- Automotive Design Competition 2023

- Our teachers celebrating new CDIC students

- New Automotive Engineering teacher joins CDIC

- Design 2 Bridge Design Competition

- Faculty & Students Experience Sharing

- Dr Nan Zhang recognised as 2023 Rising Star

- We welcome our new Automotive Engineering lecturer

- Dr Ana Peric Momcilovic honoured with the Gerd Albers Award

- Inspiring journey across borders

- Welcome Freshers!

- Welcome to the Academic Year 2023-2024

- New teacher welcomed for the new academic year

- Dr Nan Zhang revolutionises point-of-care diagnostics & the biopharmaceutical industry with Microfluidics

- First CDIC Student finishes her programme in Dublin

- 2023 CDIC Graduation Ceremony

- CDIC English Teachers Visit Dublin

- TCPEP Teachers' First Experience of CDIC

- We Welcome New TCPEP Teacher Caterina Villani

- CDIC Funded Student Presenting in Oxford

- Follow Your Passion - Interview with CDIC Student

- Meet the CATs!

- CDIC Students Performing on the Roof

- We Met to Talk About Irish Culture

- CDIC Students Learning How to Play Tin Whistle

- UCD wins the Asia Matters 2022 Higher Education Partnership

AE class visit to car manufacturing factory in Xi'an

Monday, 13 May, 2024

Introduction

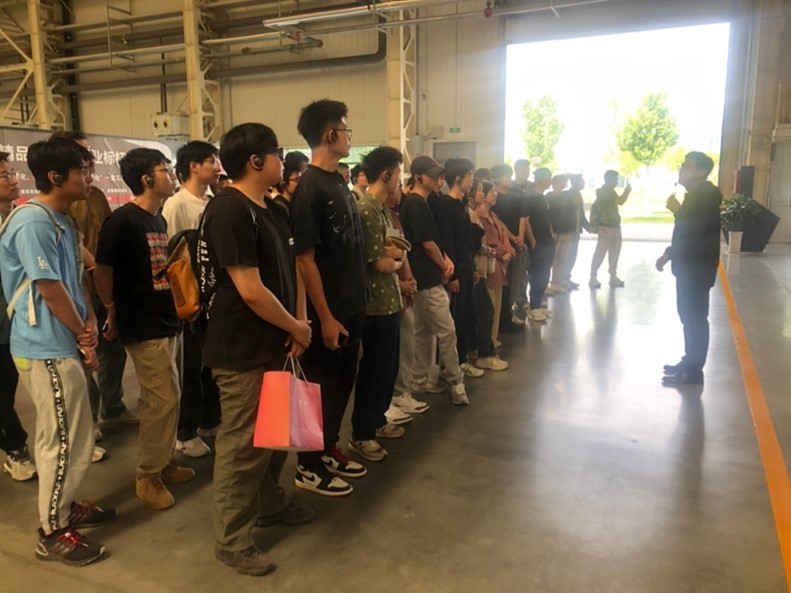

On Wed 8 May, the 4th-year students of the Automotive Engineering programme supervised by UCD teachers Dr Muhammad Sajid and Dr Xuehui Wang embarked on an enriching educational journey to the Geely Car Manufacturing Factory located in Xi'an, China. The visit aimed to provide students with firsthand insight into the automotive manufacturing processes and the cutting-edge technologies employed by one of China's leading automakers.

Overview of Geely Company

The visit commenced with a comprehensive introduction to the history and achievements of the Geely Company. Students were briefed on Geely's humble beginnings, its rapid expansion into the global automotive market, and its commitment to innovation and sustainability in vehicle manufacturing.

Automated Manufacturing

One of the highlights of the visit was the observation of Geely's automated manufacturing processes, including laser welding technology. Students witnessed the intricate choreography of robotic arms and assembly line machinery as they seamlessly pieced together various components to form the chassis, body, and interior of Geely vehicles. The utilization of laser welding technology was particularly emphasized, showcasing its precision and efficiency in joining metal components with minimal heat distortion and high repeatability. This firsthand experience offered valuable insights into the advanced manufacturing techniques employed by Geely to enhance production efficiency and product quality.

Vehicle Testing

Following the manufacturing segment, students were guided to Geely's vehicle testing facilities. Here, they had the opportunity to witness the rigorous testing protocols employed to ensure the roadworthiness and performance of Geely vehicles. From electric and hybrid SUVs to conventional models, students observed a range of vehicles undergoing comprehensive tests, including emissions testing, suspension and handling tests, and overall performance evaluations.

Interactive Sessions

Throughout the visit, students were encouraged to engage in interactive discussions with Geely engineers and technicians. They had the opportunity to ask questions, seek clarification on technical aspects of vehicle manufacturing, and gain valuable insights from industry experts.

Outcomes

The visit to the Geely Car Manufacturing Factory provided the 4th-year Automotive Engineering students with a wealth of knowledge and practical understanding of the automotive manufacturing process. Key learnings included:

1. Appreciation for the advanced technologies and automation systems utilized in modern automotive production, including laser welding technology.

2. Understanding of the importance of rigorous testing and quality control measures in ensuring the roadworthiness and reliability of vehicles.

3. Insight into the role of sustainability and environmental considerations in contemporary automotive manufacturing practices.

4. Exposure to real-world applications of theoretical concepts learned in the classroom, enhancing overall academic learning and professional development.

Conclusion

The Class Visit to the Geely Car Manufacturing Factory in Xi'an, China, was an invaluable educational experience for the 4th-year students of the Automotive Engineering Program. By witnessing firsthand the intricacies of automotive manufacturing and testing processes, students gained practical insights that will undoubtedly enrich their academic studies and future careers in the automotive industry. We extend our gratitude to Geely for their hospitality and for providing this exceptional learning opportunity.